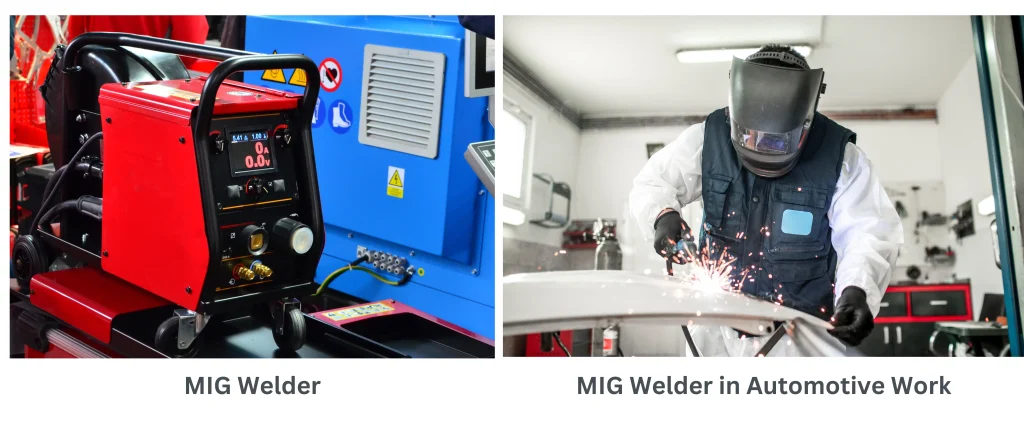

When it comes to fixing cars or creating custom builds, there are right tools that helps to do the job properly. One of the most significant tools in your arsenal is a MIG welder (mig hegesztő). However, due to the many options available on the market, selecting the right one for your automotive projects may be very tricky.

In selecting a MIG welder (mig hegesztő), one must exert caution and alertness because a good MIG welder (mig hegesztő) will greatly determine the quality of work produced. A good MIG welder (mig hegesztő) helps to produce strong and neat welds, and those thus created can hence last for quite a while. On the other hand, a wrong MIG welder (mig hegesztő) may bring up weak joints, frustration, and eventually wasting a lot of valuable time.

In this article, I will bring out everything you need to know when looking for that perfect MIG welder for your car projects—starting with the basics of MIG welding, some crucial specifications worth a look at, and top recommendations based on skill level.

MIG welding (mig hegesztő)—Metal Inert Gas welding—is where a wire is fed through a gun, creating a spark that melts the wire and metal together. The wire electrode is enveloped by a shielding gas, which protects the welding puddle from the atmosphere’s contaminants to ensure a clean and solid bond. It is popular mostly because this method is pretty easy to learn and makes quality welds.

MIG welding (mig hegesztő) is widely used in automotive work because it’s versatile and efficient. This process can be applied on different metal parts of vehicles: body panels, frames, exhaust systems, etc. Also, it happens to take less time than other types of welding, which is crucial when making multiple repairs or modifications.

Choosing the right MIG welder (mig hegesztő) is just one part of the equation. A high-quality machine is essential, but having a skilled welder to operate it is equally important. BCM Group offers highly skilled welders in MIG from India who are experienced in handling various tasks concerning welding with precision and expertise.

Ensure that your chosen MIG welder (mig hegesztő) has adequate power for auto work. Different metals require varying levels of power; therefore, pick out one with adjustable settings that can handle various materials.

The duration of welding before the machine has to rest is known as the duty cycle. In car repairs, you need a welder that can perform over long periods without breaking too frequently. A welder with a high-longer, guided, small-duty cycle will therefore enable you to keep working easily.

Consider whether you need to move the welder around. If you have a small workspace or need to transport it, choose a small, compact, and portable one that fits within your limited space (if any) if you have a congested workshop or have to carry it around often.

Verify that the welder is compatible with the metals you are going to weld, including aluminum or steel. Furthermore, ensure it possesses the appropriate accessories and settings for these materials.

Select a welder that is friendly to use as well as easy in terms of configuration. Automatic configuration and straightforward controls, such as a beginner’s guide, are good features to look out for when selecting a machine that would make your welding project quicker and more efficient.

When looking for a suitable welder for your budget, it should also have all the necessary features. In some instances, paying slightly more results in an improved gadget that would serve longer, enhancing productive output, thus justifying its additional cost.

Choosing the right MIG welder (mig hegesztő) is just one part of the equation. A high-quality machine is essential, but having a skilled welder to operate it is equally important. At BCM Group, we offer highly skilled welders in MIG from India who are experienced in handling various tasks concerning welding with precision and expertise. Our professionals are trained to get the best results from your equipment, ensuring that your automotive projects are completed to the highest standards. Properly executed with the correct welder and machine, you can achieve exceptional results in your automotive repairs and customizations.

Write Email : office@bcmgroup.in

Contact : +91 9168688833

KÖZPONT

409, 4. emelet, Amanora Chambers, Amanora Mall, Magarpatta City közelében, Hadapsar, Pune – 411028,

BCM Group Global Manpower SRL, Romania

Álláskeresőknek

Cégek számára

Cégek számára

alatt regisztrálva Ministry of External Affairs

License No. MUMBAI/PARTNERSHIP/5493853/2021

© 2024–2025 bcmgroup.Minden jog fenntartva.

Ez az oldal reCAPTCHA védelem alatt áll, és a Google adatvédelmi irányelvei, valamint a szolgáltatási feltételek vonatkoznak rá.